Do you know the manufacturing processes of PVC leather materials?

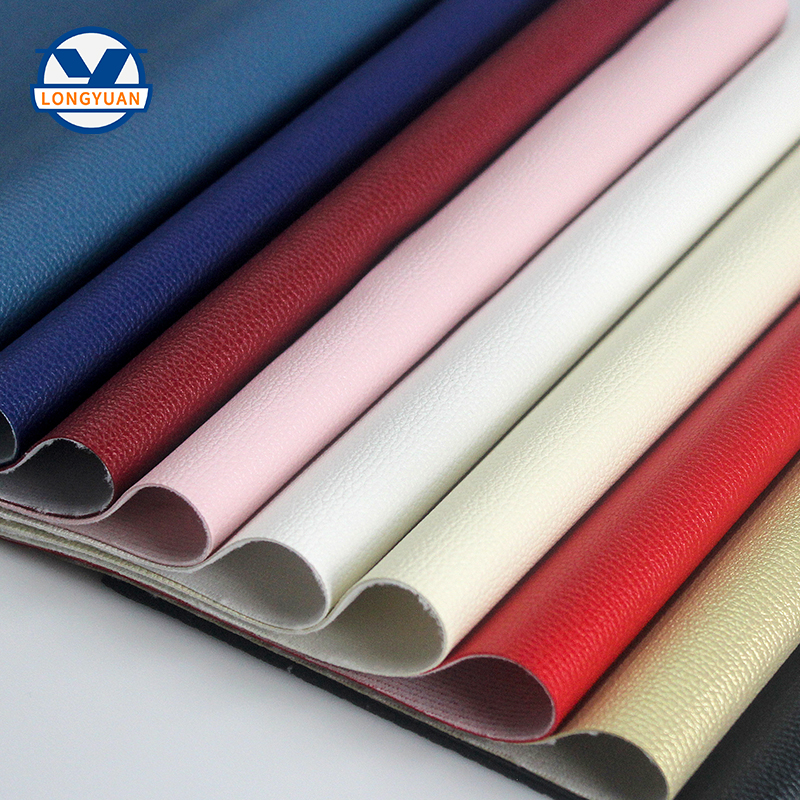

PVC leather is a kind of simulated leather, which feels similar to real leather and is soft to the touch.

Do you know what manufacturing processes are used for PVC leather materials? It is mainly divided into the following steps:

1. Printing: Color the PVC material that needs to be printed, and then use a printing machine to print it to achieve different patterns and color effects.

2. Topcoat: Topcoat the printed PVC material to make the surface smoother and improve the wear resistance and antifouling properties.

3. Bake drying: Bake and dry the PVC material after the topcoat treatment to make the topcoat stronger and avoid falling off during use.

4. Coating: Coating the dried PVC material to improve the wear resistance, waterproofness and UV resistance of the material.

5. Embossing: Pattern embossing is performed on PVC materials to give them better texture and beauty.

6. Transfer paper: This is a special printing paper that can transfer patterns from paper to the surface of PVC materials to form rich patterns.

7. Hardening: Heat and harden the PVC material to increase the hardness and strength of the material, and improve the waterproofness and durability.

8. Cutting: Cut and cut the hardened PVC material to facilitate different production and processing.

9. Packaging: Finally, the PVC leather is packaged into rolls or sheets of different specifications and forms and supplied to the market.